Y-Type™ Secondary Cleaner Reduces Carryback, Cuts Maintenance Time by 80%

Industry

Sand and Gravel

Application

Crusher conveyor

Product

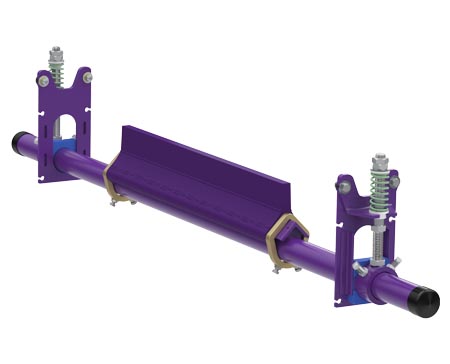

Y-Type™ Secondary Cleaner

Objective

Reduce carryback

Decrease downtime

Increase fastener life

Conveyor Detail

60" wide, 3-ply belting

Problem:

At the beginning of every shift, crushing operations at a Midwestern sand and gravel plant would come to a halt in order for the operators to clean under the discharge belt. The existing precleaner was overwhelmed by the amount of material sticking to the belt, so the carryback would build up to the point where the conveyor belt would be dragging through the abrasive material, shortening the life of the belt and the mechanical fasteners. In order for operations to run the complete shift, they would shut down the crushing conveyor and dig out the area below the belt with a skid steer loader or shovel. Both methods presented safety concerns to the people doing the work.

Solution:

The maintenance supervisor at the plant knew there had to be a better way and turned to Flexco for an answer. After examining the belt, the Flexco team specified the Y-Type™ Secondary Cleaner with a urethane blade for the belt.

Result:

Instead of shutting down every day for cleaning, the plant now only shuts down once every five days, allowing the maintenance crew to include carryback cleanup in their routine preventative maintenance program. Operators now spend less time under and around the conveyors, reducing the possibility of accidents. The use of urethane blades in the application also helped prevent premature fastener wear.

Product Group

- Belt Cleaning Systems

Product Line

- Y-Type™ Secondary Cleaner

Industry

- Sand and Gravel