Logistics Spotlight: Avoiding Product Loss and Belt Damage at the Hitch Transfer

In logistics applications (anything ranging from parcel to warehousing to distribution), you will find a variety of belt conveyor systems designed to sort many types of items – large boxes, small package parcel bags, Jiffy® bags, envelopes, etc. In these sorting facilities, you will also find “hitch” transfers. A hitch transfer usually involves a transition from a horizontal belt to an inclined belt, or from a decline to a horizontal belt, with packages moving over the head pulley of the transferring belt in a “waterfall” fashion and on to the receiving belt below.

In logistics applications (anything ranging from parcel to warehousing to distribution), you will find a variety of belt conveyor systems designed to sort many types of items – large boxes, small package parcel bags, Jiffy® bags, envelopes, etc. In these sorting facilities, you will also find “hitch” transfers. A hitch transfer usually involves a transition from a horizontal belt to an inclined belt, or from a decline to a horizontal belt, with packages moving over the head pulley of the transferring belt in a “waterfall” fashion and on to the receiving belt below.

The advantage of using a hitch in these cases is that one continuous conveyor belt with a single drive can be used. The disadvantage of using a hitch is that the envelopes and small package parcel bags being sorted can get sucked back under the drop and damaged by the bend pulley below.

Finding a solution AT YOUR CONVEYOR TRANSFER

Some operations chalk up the problems with hitch transfers to the cost of doing business, choosing to deal with angry customers receiving damaged packages or unhappy maintenance crews who must continually shut down systems to repair damaged conveyor belts and pulleys. Others set out to find a solution either by creating their own homemade mechanisms or by seeking help from the OEM.

In most of these cases, the hitch protector solutions tend to be the same: a block of UHMW screwed to an angle iron, which is positioned at the hitch and affixed to the side panels of the belt conveyor. While these fixes may limit the number of packages being sucked back into the bend pulley, they do not totally solve the problem. In fact, oftentimes, the block of UHMW causes more issues - like belt damage that leads to downtime spent on belt repairs.

Homemade solutions

Foreign object debris (FOD) is a dirty phrase in the logistics world that basically encompasses anything on the belt that wasn’t intentionally placed there. When there is FOD on the conveyor belt, there is potential for something to go very wrong. In the case of a hitch transfer that is equipped with a homemade or OEM protector that often does not adequately cover the hitch opening, part of the package can be snagged on the protector and rips can occur. Because of this, the contents of a damaged bag can spill on to the belt. This means two things: you now have a damaged package, and the contents of that package can cause serious problems at the hitch.

Foreign object debris (FOD) is a dirty phrase in the logistics world that basically encompasses anything on the belt that wasn’t intentionally placed there. When there is FOD on the conveyor belt, there is potential for something to go very wrong. In the case of a hitch transfer that is equipped with a homemade or OEM protector that often does not adequately cover the hitch opening, part of the package can be snagged on the protector and rips can occur. Because of this, the contents of a damaged bag can spill on to the belt. This means two things: you now have a damaged package, and the contents of that package can cause serious problems at the hitch.

Let’s say that package we just talked about is an assembly package for a furniture set. When it tears, all the pieces come pouring out – an Allen wrench, knobs, nuts, and screws. What happens when one of those screws gets jammed under the homemade hitch protector? It slices the conveyor belt like a knife as it travels under the block. In the case of a garment bag being torn, someone’s holiday gift is strewn across the belt and eventually slides past the block, getting tangled around the bend pulley, and causing failure of the belt splice.

Here’s a real-life example of a homemade solution that was causing damage to packages and the belt.

Another problem that occurs when using a solid block of UHMW to protect the hitch is that if a package, envelope, or polybag does get lodged between it and the belt, something must give. Either the package is destroyed, the conveyor belt is damaged, or the whole block fails, leaving the hitch transfer unprotected. With the transfer unprotected, more items can be pulled in to the bend pulley, resulting in catastrophic belt failure.

What about small parcel shipping bags? These are the heavy duty multi-use bags used to convey a group of small packages through the sortation system and onto the sortation system for small packages or “smalls.” When a shipping bag gets caught in a hitch, it quite often leads to a catastrophic breakdown situation. Not only is the sortation system stopped, but many customer packages are likely damaged in the process.

What to look for in a hitch protector

You certainly don’t want a solution that is going to cause you even more problems, so if a solid block of UHMW isn’t the answer, then what is?

You certainly don’t want a solution that is going to cause you even more problems, so if a solid block of UHMW isn’t the answer, then what is?

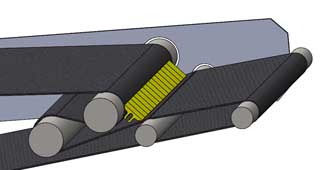

An engineered solution – one that has segments, rather than a solid piece – is the answer. This segmented design is useful, allowing only a portion of the guard to dislodge before a jam occurs, preventing damage to both the package and the conveyor belt.

You’ll also want to look for a hitch guard with low friction, so it won’t damage your packages or cause you packages to get stuck, but one that is durable enough to stand the test of time.

It is important to pay special attention to the mounting system on the hitch guard. After all, your hitch guard is only useful if it is installed properly. Select a hitch guard that can be adjusted for an optimal guard-to-belt fit that discourages material jamming. Check out this real-life example of how the tight seal of an engineered hitch guard saved the day for a large parcel handling operation.

Finding a hitch guard system that works with scanner eye systems may also be necessary, depending on your application and should be an available option.

Not only should your hitch guards be easy to install, but they should also be easy to maintain. When a segment does release due to FOD, a belt flap, or a damaged splice jarring it loose, a brightly-colored hitch guard ensures that maintenance crews can easily see when a segment has dislodged. And a new segment can be snapped into place in seconds for a quick and easy repair.

Flexco Hitch Guards could be the engineered solution you are seeking. Learn how our easy-to-install hitch guards can protect your transfer by clicking here.

Authored by: Todd Stewart, Industry Manager

Stewart has been with Flexco for almost 30 years, working in various roles from customer service, to manufacturing, to training and new product development. As Industry Manager, Stewart thoroughly researches target industries, creating programs to support each industry and identifying customer issues, as well as potential product solutions. Stewart currently leads the development of the Parcel Handling Industry Program and is responsible for ensuring that Flexco is positioned to serve the needs of our global customers. Stewart earned a bachelor’s degree in Marketing with a B2B specialty from Davenport University.

Subscribe to the Flexco Blog

Published Date

November 20, 2018Product Group

- Belt Accessories

Industries

- Parcel Handling

- Warehousing and Distribution

Issues

- Belt Damage

- Product Loss