Common Bar Hook Fasteners vs. Carded Hooks – Which Do I Choose for my Light-Duty Belt Splice?

Wire hooks have long been the go-to fastener of choice for those in a variety of industries looking for a quick, easy, and durable way to splice their belts. But within the wire hook product line, there was often discussions on which type to use – carded or common bar hook. We thought a blog would be a great way to break down the benefits of each so you can make an informed decision when splicing your next belt.

Wire hooks have long been the go-to fastener of choice for those in a variety of industries looking for a quick, easy, and durable way to splice their belts. But within the wire hook product line, there was often discussions on which type to use – carded or common bar hook. We thought a blog would be a great way to break down the benefits of each so you can make an informed decision when splicing your next belt.

How are wire hooks used?

Over the years, wire hooks have been designed with a variety of wire diameters, leg and point lengths, metals, strip lengths, and styles, offering greater flexibility in tailoring the wire hook to specific application needs. The double staggered grip pattern gives wire hooks exceptional holding power without degrading the integrity of the belt carcass. They are low-profile, making them compatible with conveyor components and compliant with the need for reduced operating noise. Wire hooks are typically used in parcel and baggage handling, general manufacturing, commercial laundry, food processing, agriculture, and filter media.

| What is the difference between Carded Hooks and Common Bar Hook Fasteners? |

|---|

Carded hooks are simply individual hooks that are secured on carding paper. Flexible and available for use in a variety of applications, carding paper makes handling the hooks safe and easy. Carded hooks are simply individual hooks that are secured on carding paper. Flexible and available for use in a variety of applications, carding paper makes handling the hooks safe and easy. |

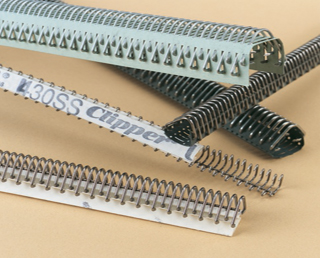

Common bar hook fasteners are formed by welding each hook to a common bar. The welded bar creates a stable strip of fasteners to eliminate damage during handling. They contain a safety strip that covers the hook points to protect the fingertips, yet is easily removed prior to lacing. Common bar hook fasteners are formed by welding each hook to a common bar. The welded bar creates a stable strip of fasteners to eliminate damage during handling. They contain a safety strip that covers the hook points to protect the fingertips, yet is easily removed prior to lacing. |

Which is better for my application?

Which is better for my application?

In many cases, the decision to use carded hooks or common bar hook fasteners depends on each operator’s preference. However, both the carded hooks and common bar hook fasteners have their own benefits.

In the case of carded hooks, for example, their flexibility makes them essential for use with bias splices and troughed belt applications. Common bar breakage is a concern in these applications, so carded hooks are preferred. Carded hooks are available in several different specialty metals, meeting the needs of a wide range of applications.

If flexibility is an advantage for carded hooks, then rigidity is an advantage for common bar hook fasteners. The welded bar creates a flat, finished splice so that belt “wave” is eliminated. Under abusive applications, the welded common bar also helps to distribute the load across the full width of the splice to protect individual hooks.

Common bar hook fasteners as a maintenance solution

The common problem of belt wave, which results from carded fasteners being installed on a thinner belt, is prevented by the common bar that is welded to all the hooks. This same bar allows the splice to ride flat on a conveyor system, making it more compatible with conveyor transfer points and components.

Since the hook legs are held parallel to each other through the welding of the bar, individual fasteners can’t tip side-to-side. This benefit allows an installer to perform routine maintenance quickly by easily removing the pin, working on the conveyor, and reinserting the pin. During the installation process, handling fasteners is easier because if a strip is dropped, individual hooks will not dislodge from the strip as in the case of carded hooks.

The bottomline

The bottomline

So as you can see, the choice between carded and common bar hook fasteners is largely one of belt type, application, and preference. Flexco’s Clipper® Wire Hook Fastening System features both types as illustrated on our Web site when you click here. And our “Help Me Choose” tool can help you narrow your fastener selection based on your specific needs. Regardless of what you choose, we are confident that the low profile design and exceptional holding power, along with the quick installation options, will suit your needs.

Authored by: Ramses Banda Marquez, Product Manager

Banda Marquez manages the overall marketing strategy and activities associated with the light-duty mechanical fastener line and belt conveyor products. He brings expertise in marketing, product management, operations, engineering, and supply chain management to Flexco, along with extensive experience in distribution and international business. Banda Marquez also holds patents in both the U.S. and Australia. Banda Marquez earned a bachelor's degree in Mechanical Engineering from Baja California State University and a master's degree in Project Management from Keller Graduate School of Management.

Subscribe to the Flexco Blog

Related Blogs

Published Date

January 22, 2019Product Group

- Mechanical Belt Fastening Systems

Issues

- Downtime

- Maintenance

- Splice Consistency