Clipper® Wire Hook Splice = Fastener Strip + Pin + Installation Tool

Step 1

Measure belt thickness

Use the Clipper hook gauge, micrometer, or caliper to measure belt thickness. If the belt has an impression cover, skive cover 1” (25 mm) back from belt end prior to measuring. Do not cut belt carcass.

Step 2

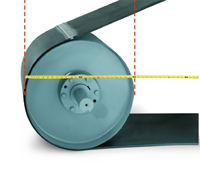

Measure pulley diameter

The minimum pulley diameter is the smallest pulley that has a belt wrap of at least 90°.

Step 3

Determine hook choices

Refer to the hook selection chart and locate belt thickness on top of the chart and minimum pulley diameter on the left side. Using the matrix, determine the hook sizes most appropriate for your application. Do not select hooks that specify a larger minimum pulley – the leg length will be too long, causing leg fatigue and premature failure.

Step 4

Select hook wire diameter

Hooks are produced in various wire diameters. A splice made from a smaller wire diameter is quieter and wears less as it contacts conveyor components. A splice made from a larger wire diameter offers greater strength and abrasion resistance. Refer the “Wire Diameter” column on the hook selection chart. Choose a hook with a wire diameter that best suits your needs.

Step 5

Select style

Choose between Unibar® and carded fasteners based on your application requirements. All Unibar offerings begin with “u” (UCM, UX1, U2, etc.).

Step 6

Select material

Refer to the material selection chart for the metal characteristics which best suit your application. Not all sizes and styles are available in all metals.

Step 7

Select connecting pin

Connecting pins are the vital link that, when combined with properly selected and installed hooks, complete the perfect splice. The wide selection of materials and sizes in the pin selection chart lets you match a connecting pin to the special needs of your application.

Step 8

Choose your installation method

The wire hook splice is machine installed, yielding a precise, strong and smooth splice. Choose from a variety of Clipper Wire Hook Installation Tools to match hand, power, production, or special application lacing needs.