TRANSFER CHUTES

What we know: Material Transfer Science

With over 100 years of experience in the belt conveyor industry and more than 30 years of experience in transfer chute technology, Flexco has a long history of handling materials safely and efficiently. We apply our understanding of material transfer science from projects around the world to design an optimal transfer chute solution for your operation.

In order to provide you with the best solutions, the Flexco engineering team works closely with you and your team to provide transfer points with exceptional operating capabilities. As part of our service, we analyze everything from belt speed, to material type, to environment to help you decide whether a complete upgrade or refurbishment is the right path for your operation.

Flexco takes a holistic approach to transfer point design that goes beyond the chute conveyor, providing guards, safety cages, wear plates and skirting systems as supporting products for your transfer chute, as well as cleaners, wash boxes, and more.

CoNNect with Flexco Experts

Discover why customers around the world trust Flexco to assess their belt conveyor systems and increase their productivity. Schedule an assessment of your transfer system or talk to a Flexco expert about your needs.

Tasman Warajay® Technology

Tasman Warajay Technology is the culmination of our 30 years of experience with designing transfer point solutions, incorporating our proven transfer point engineering method, flow design tools, surveying techniques, manufacturing philosophy, project guidance, and installation support. Flexco FlowFirst™ transfer points, created with Tasman Warajay Technology, stand as the global benchmark for transfer point solutions.

Tasman Warajay Technology is the culmination of our 30 years of experience with designing transfer point solutions, incorporating our proven transfer point engineering method, flow design tools, surveying techniques, manufacturing philosophy, project guidance, and installation support. Flexco FlowFirst™ transfer points, created with Tasman Warajay Technology, stand as the global benchmark for transfer point solutions.

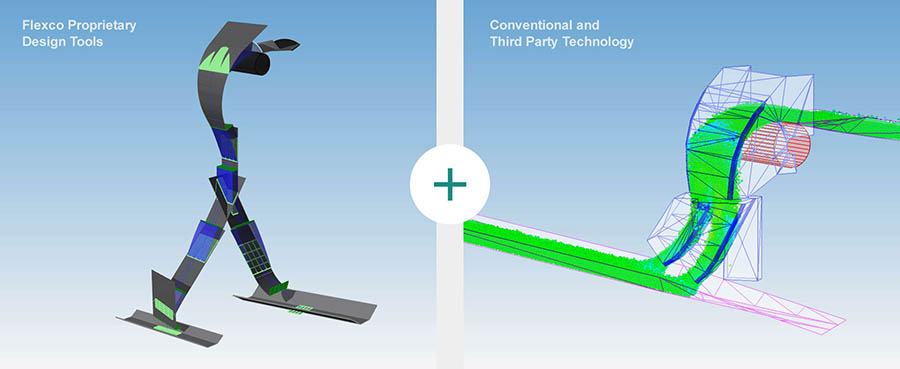

Flow Design Tools

Flexco Tasman Warajay Technology combines our proprietary design tools with industry-available tools, such as Discrete Element Modeling (DEM). Our experts use the best flow design methods to develop a solution that fits your specific transfer point challenges.

Flexco Proprietary Design Tools

Flexco first began to address bulk material handling challenges at Australia export facilities, before Discrete Element Method and other analytical tools were on the market. At these ports a team of engineers and mathematicians developed calculations and design rules that proved effective in accurately predicting how material flowed throughout a transfer point. Through the years these calculations were refined and incorporated into our proprietary transfer point software. The basis of this technology is an interactive flow control design tool that goes beyond guess-and-check analysis and actually drives to a purposeful solution. Today this expertise remains at the heart of our design tools — known as Tasman Warajay Technology.

Conventional and Third Party Technology

Since 1985, Flexco has been refining industry standards and our experience-based design rules. Building on this rich foundation of knowledge, we have developed a design methodology that is second-to-none in the industry. These experience-based rules alone set us apart and are complemented by our Discrete Element Method analysis tools, along with our proprietary software. Since Flexco has access to all the industries’ available design tools and our own proprietary software, we are uniquely positioned to provide you with the best transfer point solution.

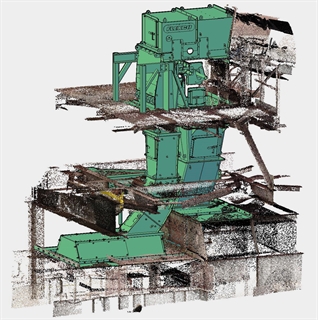

Proprietary Surveying Techniques

Flexco combines the latest in surveying technology with our own proprietary techniques to provide easy installation, even when retrofitting existing solutions. By using Tasman Warajay Technology with state-of-the-art 3D scanning tools, Flexco can model a highly precise representation of your structure – ensuring that your transfer point is installed right the first time.

WHAT WE DO

Developing the Right Solution for Each Application

With over 100 years in the belt conveyor industry, Flexco has seen nearly every type of transfer point challenge, and developed a full range of innovative solutions. Discover the process we use to assess your application and develop the right solution to meet your unique needs.

WHAT WE'VE DONE

Industry Expertise

For materials like coal, metallic ores, fertilizers, biomass, grains, and everything in between, Flexco has the expertise to help design and apply a solution that is right for your industry. See examples of our work with a variety of industries and materials.

FLEXCO TRANSFER CHUTES

TRANSFER POINT SOLUTIONS FOR ALL INDUSTRIES, DESIGNED AROUND YOUR SPECIFIC NEEDS

CoNNect with Flexco Experts

Discover why customers around the world trust Flexco to assess their belt conveyor systems and increase their productivity. Schedule an assessment of your transfer system or talk to a Flexco expert about your needs.