TRANSFER CHUTES

What We’ve Done: Industry Expertise

With more than 100 years of helping customers with the material transfer needs across the globe, Flexco is a trusted partner in many industries. We have tackled the world’s toughest transfer points — from materials like coal and metallic ores to fertilizers, biomass, grains, and everything in between. In each application, from small to large, we focus on providing the right transfer point solution that can keep your material flowing.

Mining

-

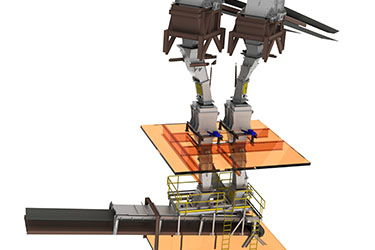

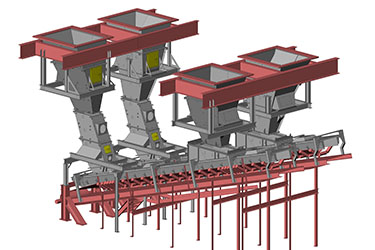

Project Profile: 1-on-2 Feeding PRB Coal to Two Crushers

Project Profile: 1-on-2 Feeding PRB Coal to Two Crushers

Challenge: A Powder River Basin coal mine needed to control material flow to their two large roll crushers. Mine operators wanted a controllable split to help deliver coal evenly to the rail car loading operation.

-

Project Profile: Potash Diverting Transfer

Project Profile: Potash Diverting Transfer

Challenge: The potash mine was experiencing a dramatic drop in productivity every time a shift change occurred, with production curtailed while miners exited and entered the mine. This resulted in a loss of productivity for the mine operations.

-

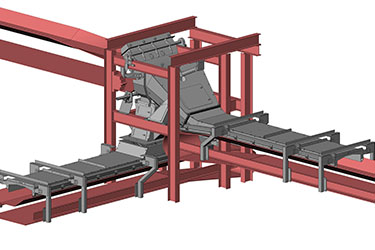

Project Profile: 90° Potash Mine Transfer

Project Profile: 90° Potash Mine Transfer

Challenge: After experiencing increased demand at the mine, the existing transfer chutes were having difficulties with the increased material being conveyed. Specific problems included frequent plugging of the transfers and issues with spillage and dust generation.

Processing plants

-

Project Profile: 89 Percent Decrease in Dust Generation

Project Profile: 89 Percent Decrease in Dust GenerationChallenge: The power plant's outdated transfer chutes to manage North American Powder River Basin Coal failed to meet OSHA's respirable dust level requirements, risking employee health.

-

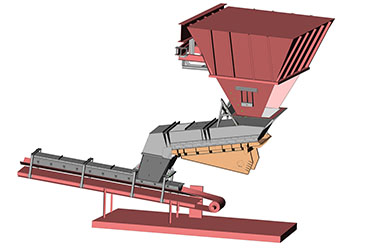

Project Profile: Barge Unloading to Conveyor

Project Profile: Barge Unloading to ConveyorChallenge: The old feeder and chutes on a barge unloading system could not consistently meet the desired feed rate of 1,200 tph and was prone to “flushing” wet material. Spillage and chute problems (buildup, plugging, and leaking) were common. Frequently, these problems resulted in costly delays in ship unloading operations. Additionally, coal spilled on the ground caused a safety hazard, and coal washed into the river was a violation. The facility incurred excessive housekeeping costs to keep the area around the chute in a suitable condition.

-

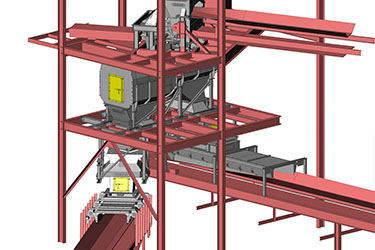

Project Profile: Granulators to Conveyors at Midwest Power Plant

Project Profile: Granulators to Conveyors at Midwest Power PlantChallenge: The old chutes were prone to plugging and material build-up. There was a large amount of dust generated and spillage through the entire load zones of the two conveyors. Additionally, coal spilled on the floor and catwalk caused a severe safety hazard to personnel. Because of this, the facility had excessive housekeeping costs to ensure the area around the chute was kept in a suitable condition.

-

Project Profile: Time Weighted Average Dust Levels

Project Profile: Time Weighted Average Dust LevelsChallenge: A power plant was adding North American Powder River Basin (PRB) coal to its fuel mixture. Management was concerned about the safety issues associated with the combustible nature of the PRB coal dust and wanted to take steps to minimize it. The new chute systems had to contractually deliver dust generation performance below the Occupational Safety and Health Administration (OSHA) respirable dust standard of 2.0 mg/m3 on an eight hour time weighted average (TWA).

Transportation Facilities

-

Project Profile: Tripper to Stacker/Bypass – 17 Pecent Throughput Increase

Project Profile: Tripper to Stacker/Bypass – 17 Pecent Throughput Increase

Challenge: Iron ore pellets can cause plugging at higher throughputs, which the port's operations group observed as their volumes increased. The old chute also resulted in unacceptable levels of spillage and dust.

-

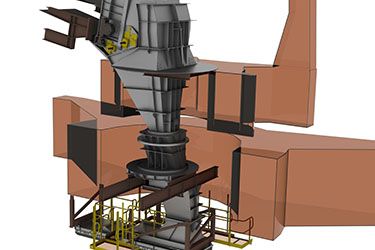

Project Profile: Sulphur Transfer Tower

Project Profile: Sulphur Transfer Tower

Challenge: Operators at a sulphur export terminal weren’t satisfied with the existing transfer chute because there was a significant amount of airborne dust that left a yellow haze on everything. Not only was this labor intensive and expensive to clean and maintain, but it resulted in hazardous working conditions and complaints from the terminal’s neighbors.

-

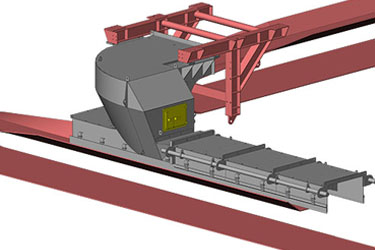

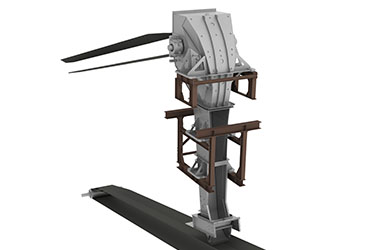

Project Profile: Reclaimer

Project Profile: Reclaimer

Challenge: As part of a terminal capacity upgrade/expansion, a design was requested for a reclaimer transfer chute system with boom arm pivoting up and down and, at the same time, slewing around the vertical axis. The 2000mm wide feed conveyor runs at 4.2m/s and the 1600mm wide receiving conveyor at 6.1m/s.

-

Project Profile: Ship Loading Various Capacity And Speed Transfer Chutes

Project Profile: Ship Loading Various Capacity And Speed Transfer Chutes

Challenge: As part of a terminal capacity upgrade, this transfer was required to increase capacity to 8000tph using the same conveyors at approximately double their original speed. The 1800mm wide feed conveyor runs at 8.5m/s and the receiving conveyor at 9.1m/s. Additionally, the transfer must be capable of running at various speeds and capacities.

If you have a challenging transfer point, or are just looking to maximise your transfer chute throughput, we invite you to check out our real-life results to find out how Flexco has helped operations with their material transfer needs.

CoNNect with Flexco Experts

Discover why customers around the world trust Flexco to assess their belt conveyor systems and increase their productivity. Schedule an assessment of your transfer system or talk to a Flexco expert about your needs.

FLEXCO TRANSFER CHUTES

TRANSFER POINT SOLUTIONS FOR ALL INDUSTRIES, DESIGNED AROUND YOUR SPECIFIC NEEDS

WHAT WE KNOW

Material Transfer Science

There's a science to your transfer point needs. Depending on the materials, loads, and environment, your needs will vary. Learn about our process for addressing your unique transfer point challenges.

WHAT WE DO

Developing the Right Solution for Each Application

With over 100 years in the belt conveyor industry, Flexco has seen nearly every type of transfer point challenge, and developed a full range of innovative solutions. Discover the process we use to assess your application and develop the right solution to meet your unique needs.